Investing in companies that drive the future

We focus on venture capital, value creation, and growth equity for life-changing technologies and sustainable solutions.

Value-led,

profit-driven

We invest in the companies we want to see on a larger platform, joining their teams along the journey to maximize value and generate lasting

positive outcomes.

Unparalleled global access

Meaningful partnerships

Our portfolio

Upside Foods, formerly known as Memphis Meats, develops meat produced directly from animal cells without the need to ra...

BioTech

•

2015

Upside Foods, formerly known as Memphis Meats, develops meat produced directly from animal cells without the need to ra...

BioTech

•

2015

Zipline is a next-generation logistics company. A Zip is a small UAV (unmanned aerial vehicle) designed with a high lev...

Logistics

•

2017

Zipline is a next-generation logistics company. A Zip is a small UAV (unmanned aerial vehicle) designed with a high lev...

Logistics

•

2017

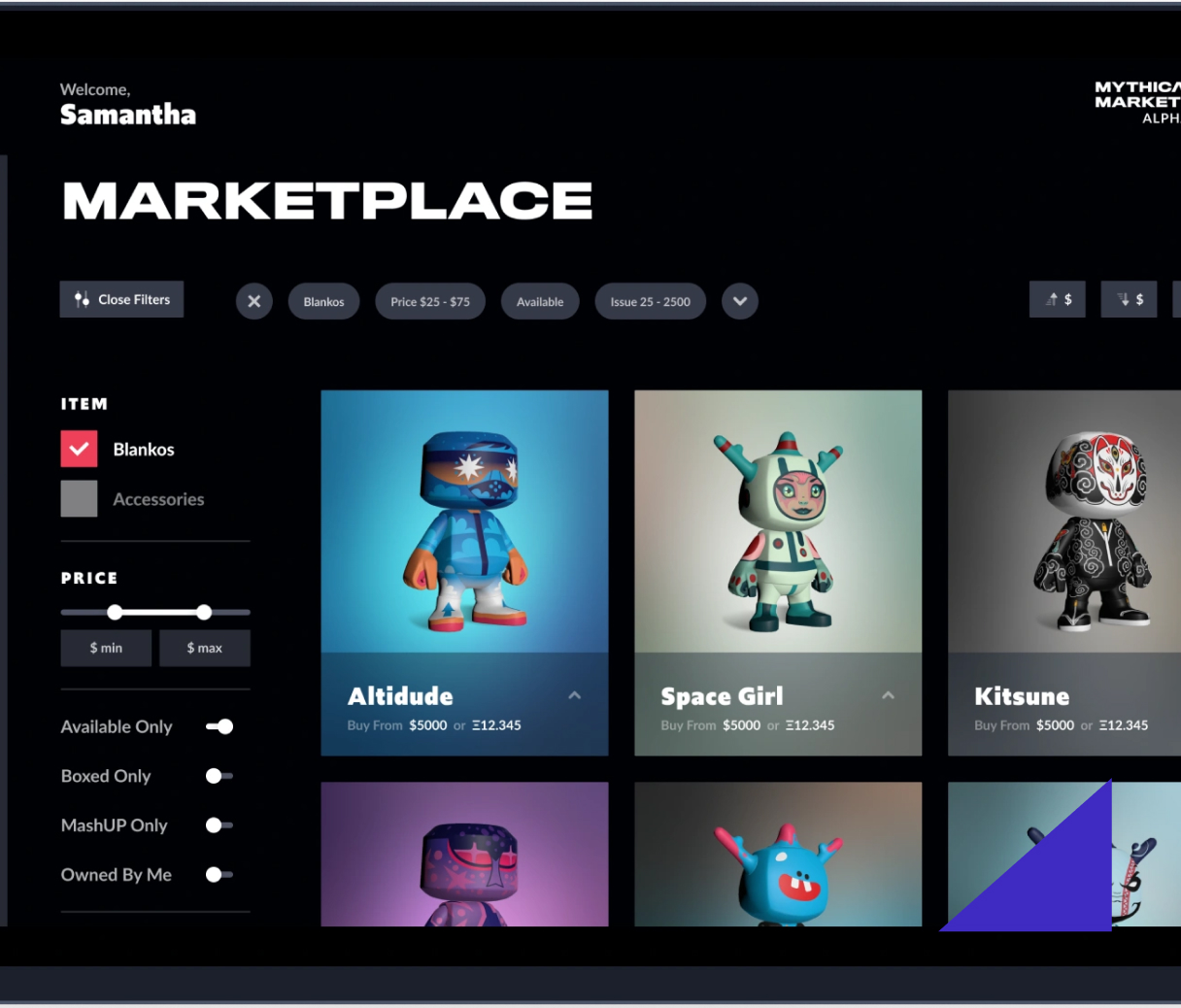

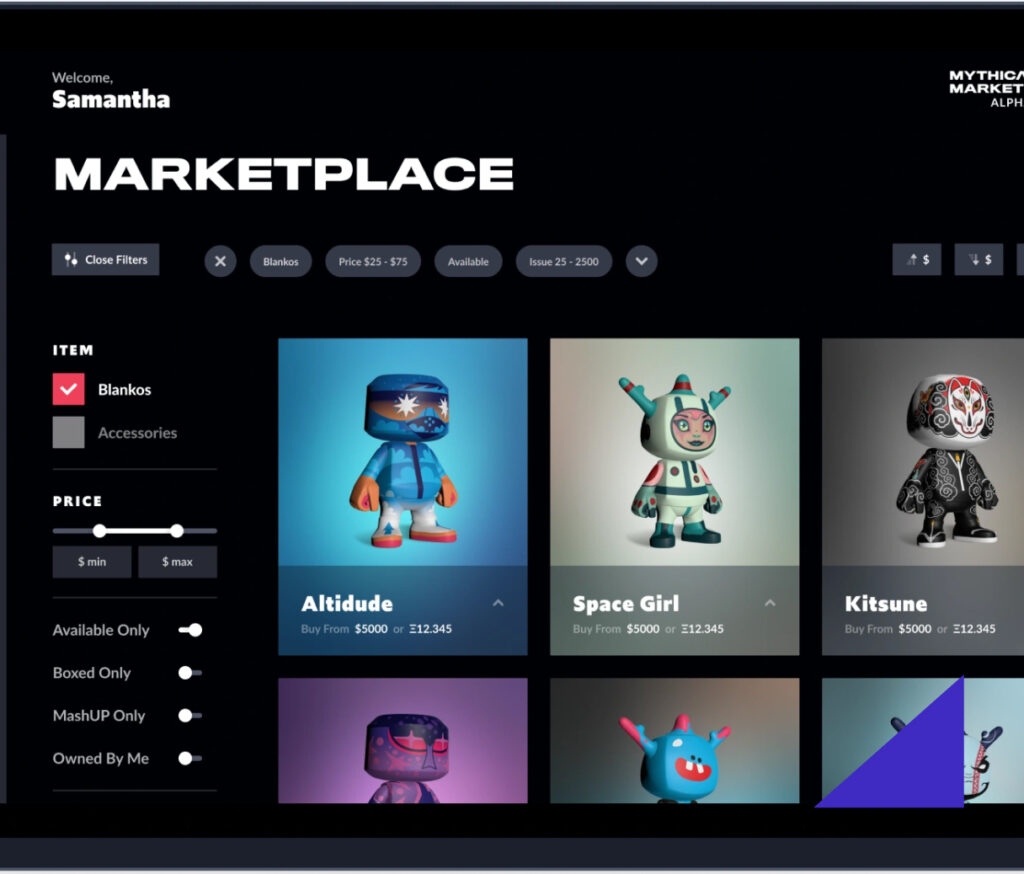

Mythical Games is a gaming technology studio intended to bring players, creators, brands, and game developers together ...

Gaming

•

2018

Mythical Games is a gaming technology studio intended to bring players, creators, brands, and game developers together ...

Gaming

•

2018

BlueNalu’s mission is to be the global leader in cellular aquaculture, providing consumers with great tasting seafood p...

BioTech

•

2017

BlueNalu’s mission is to be the global leader in cellular aquaculture, providing consumers with great tasting seafood p...

BioTech

•

2017

Many of the foods we love, the medicines we need, and the cosmetics we use daily rely on a single ingredient—gelatin. F...

BioTech

•

2015

Many of the foods we love, the medicines we need, and the cosmetics we use daily rely on a single ingredient—gelatin. F...

BioTech

•

2015

Upside Foods, formerly known as Memphis Meats, develops meat produced directly from animal cells without the need to raise and slaughter...

BioTech

•

2015

Zipline is a next-generation logistics company. A Zip is a small UAV (unmanned aerial vehicle) designed with a high level of...

Logistics

•

2017

Mythical Games is a gaming technology studio intended to bring players, creators, brands, and game developers together through personalized experiences and...

Gaming

•

2018

BlueNalu’s mission is to be the global leader in cellular aquaculture, providing consumers with great tasting seafood products that are healthy...

BioTech

•

2017

Many of the foods we love, the medicines we need, and the cosmetics we use daily rely on a single ingredient—gelatin....

BioTech

•

2015

Driving value

across industries

To us, every successful idea is an opportunity. We tailor our approach to each of our portfolio companies, spanning a wide range of industries that includes:

BioTech

Harnessing cellular and molecular processes to reshape entire industries and better understand our relationship with biology.

FinTech, Web3, and Gaming

Integrating and improving day-to-day interactions for people globally.

D2C and SaaS

Streamlining our changing world through products and services.

Human and Planetary Health

Supporting a growing global population through system design, sustainability, and healthcare.

In the media

Led by Prince Khaled bin Alwaleed bin Talal Al Saud

As a figure of business, technology enthusiast, and investor, HRH Prince Khaled bin Alwaleed bin Talal Al Saud is a firm proponent of clean energy, healthy living, the humane treatment of animals, and a motivated voice for entrepreneurship.